Today, based on my study and reflections, I'll outline the development process for vehicles.

It's important to note that the development process is not limited to these steps alone. Building a vehicle involves extensive testing and a significant amount of human resources. In fact, automobiles are often referred to as products of testing due to the extensive validation required. So, while I'll provide an overview, it's essential to understand that the actual process is far more complex than what I'll describe here.

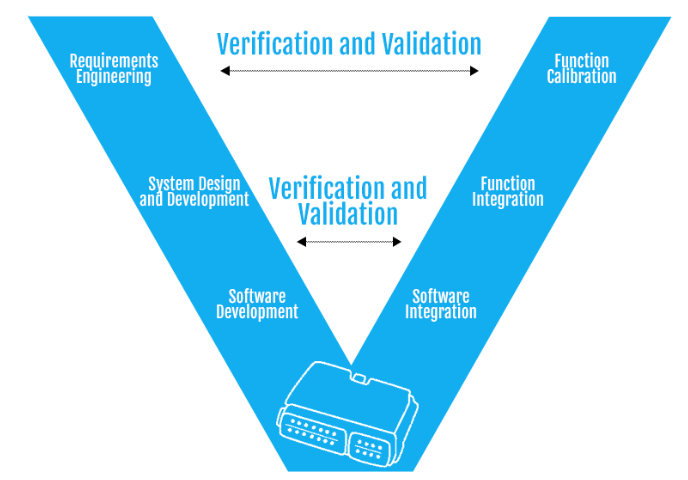

Here's how you can break down the vehicle development process, starting from the top left corner:

- Requirements Analysis

- System Design

- Software Design (Development)

- Code Generation

- Software Integration

- Function (Hardware) Integration

- Real Vehicle Testing (Functional Measurement)

Remember these steps as a guideline for understanding the vehicle development process.

Here's a more detailed explanation:

- Requirements Analysis: The specifications provided by the parent company (OEM or Tier 1) are analyzed to understand the functionalities and logic. If the functionality is deemed acceptable, it is modeled using Matlab Simulink.

- Matlab Simulink Modeling: The code generated using Matlab Simulink is then converted into an executable image for use in vehicles, typically using the Mobisyn (AUTOSAR platform). This process involves uploading the project files created in Matlab Simulink to Mobisyn.

- Trace32 Integration: The image extracted using Mobisyn is uploaded to the test vehicle board memory using Trace32. Trace32 is a program used for debugging and testing purposes, akin to having a display in Windows to view programs' actions. This step helps ensure the code operates correctly within the vehicle's environment.

- Testing with CANoe16 SP4 and Trace32: Testing is conducted using CANoe16 SP4 and Trace32 to evaluate the input/output values. For instance, if there is no change in output values when sending the Ignition1 Signal from CANoe to Trace32, it suggests a potential communication issue, which may require investigation into the control unit code integration.

- Code Integration and Final Testing: Once all individual parts of the code have been sent to the integration team and integrated, the code is converted and optimized. If no errors are found during integration, final real-vehicle tests are conducted before mass production.

Even though it's a bit rough, looking through the text above, you might gain some insights into the V-Cycle. I feel like I did. Anyway, that's it for today's information record.

Source of the image: https://www.einfochips.com/blog/v-model-in-automotive-software-development/